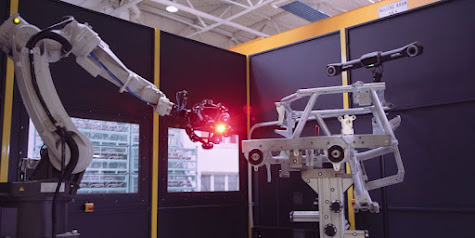

It is essential to maintain machine components machine design to ensure that equipment will meet the requirement. Durobyte builds custom machine designs to exact specifications and provides Custom Machine Building Solutions to develop the perfect system. We provide high-quality service and custom machinery to a wide range of companies. We help to improve productivity and increase revenue.

The different types of custom machine building services:

Our experts meet several custom machine building

needs with proper knowledge, skills, and the most advanced technology in

machinery operation. Custom machines enhance operational efficiency, safety,

and ease of operation.

·

Welding and fabricating of the base

·

Machining of components parts

·

Procurement of commercially available components

·

Complete mechanical assembly

·

Wiring of main control cabinets

·

Final skidding, crating, and shipping

Custom machines perform tasks endlessly without

slowing down or tiring and increase your production process's efficiency. With a lower number of errors, you can save the cost of replacing damaged ones. If you are

considering investing in custom machinery, consider these three advantages.

·

Quality Control

·

Higher Profits

·

Greater efficiency

Machine builders

Building a machine is one of the biggest

challenges. Machine builders Ontario

reduce commissioning costs and track the device's availability and shorten

commissioning times. Machine builders remotely check the problem of technical

problems during the warranty period. There is no need to visit the customer to

solve the issue. For future machine designs, the data provided can be used for

optimization approaches. Machine builders meet the client's demands and

increase their productivity.

Essential requirements for machine builders:

·

For machine builders, manufacturers have essential requirements:

·

Through demonstrated simulations, the flexibility of a machine design can

be shown.

·

For predictive maintenance, production of quality parts and capabilities

are confirmed.

- Operator training can be accomplished proactively before the machines.