Automated Quality Inspection helps to compare the content at different stages. An automated quality inspection system in Canada is handled by the production line operators and quality technicians. To meet the specific machinery needs for manufacturers across all industries an inspection system and process be highly customized.

Benefits of Automated Quality Inspection System

· Improve the product quality

To improve the product quality Automated Quality Inspection

System Canada is best. Manual quality inspection is labor-intensive and

prone to human error. With quality inspection process is labor-intensive and

prone to human error. The quality inspection process becomes more accurate and

repeatable and also ensures that products are produced at the highest quality

levels. This process is very quick.

· Business Growth

Quality inspections help facilitate business growth. The

quality inspection process has a positive impact on the bottom line of the

company. If the overall quality of the product is improved that means products

are much in demand. The quality data help to make a decision that is attractive

to potential buyers.

· Cost-effective

One of the most effective processes is automating quality

inspection. The upfront cost is associated with the inspection system.

Employees are paid more as they become more experienced but the automated

inspection system doesn’t involve extra cost.

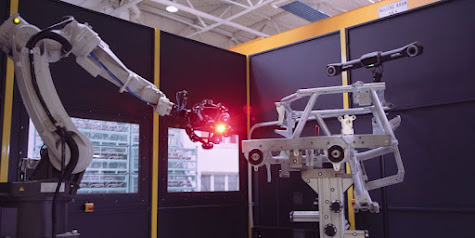

What is Assembly Automation System Ontario?

Assembly Automation System is a wonderful innovation and there are a lot of benefits that the

company will get out of it. One of the best benefits of automated assembly is

the quick turnaround. The machinery reduces the turnaround time as it is used

smartly and efficiently. Combine several assembly capabilities or production

steps into one single step. Assembly Automation System

Ontario machines offer high-quality production and enhance production

quality.

Original Content Source Here:-